07

2024

-

09

Types and Applications of High Speed Steel End Mills

High-Speed Steel End Mills (HSS End Mills) are a kind of cutting tools used for milling, mainly used for processing metal, plastic and other materials. The “end” of end mill refers to the perpendicular relationship between the tool axis and the cutting surface, while “high-speed steel” indicates the characteristics of the tool material.

High-speed steel (HSS) is an alloy steel containing elements such as tungsten, molybdenum and vanadium, which has excellent wear resistance, heat resistance and cutting performance. HSS end mills are able to maintain stable performance at higher cutting speeds and are suitable for general milling tasks. It can effectively cut a variety of metallic and non-metallic materials.

With its high hardness and wear resistance, HSS is not prone to tool wear during prolonged use and can provide high machining accuracy and surface finish, making it suitable for demanding machining tasks.

Classification of High Speed Steel End Mills

Flat End Mills: The end face of the tool is flat, suitable for plane milling and flute machining, capable of efficient cutting.

Ball End Mills: The end face of the cutter is hemispherical, suitable for curved surfaces and contour machining, capable of realizing complex shape machining.

Grooving End Mills: With specially designed grooving flutes for cutting flutes and grooves, they are suitable for machining in narrow spaces.

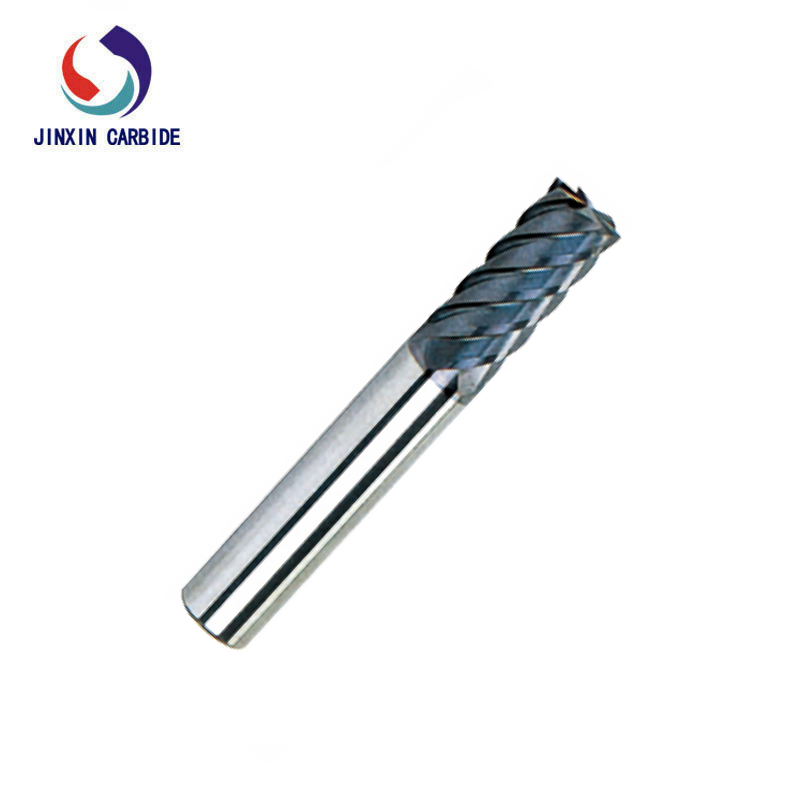

Helical End Mills: The cutting edges of the tool are distributed along the helix, which is suitable for machining at higher cutting speeds, and can provide steady cutting effect and better chip removal capability.

End Mills: With cutting edges along the end face and periphery of the tool, they are suitable for bottom and side milling of holes and are commonly used for making holes and steps.