17

2025

-

10

What are the applications of Heavy Duty Cutting Insert?

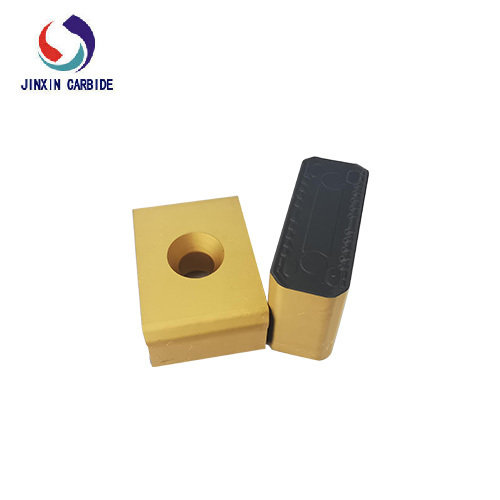

Heavy-duty cutting inserts are designed for high-intensity, high-load cutting environments. Compared to conventional inserts, heavy-duty cutting inserts have higher structural and material requirements. They typically utilize a high-strength carbide substrate with a wear-resistant coating (such as TiCN, Al₂O₃, TiAlN, etc.), effectively withstanding the high temperatures and impact forces generated during cutting.

The characteristics of heavy-duty carbide inserts make them suitable for use in heavy machinery manufacturing, the petroleum and natural gas industry, and the aerospace industry.

1. Heavy Machinery Manufacturing: These inserts are used in machining large mechanical components such as gear shafts, hydraulic cylinders, and connecting rods, requiring large workpieces and deep cutting depths. Heavy-duty Turing inserts maintain high removal rates while ensuring dimensional accuracy and surface quality. For heavy equipment manufacturers focused on productivity, these inserts offer significant cost advantages.

2. Oil and Gas Industry: These inserts are used to machine components such as valve bodies, drill pipes, casing, and flanges, often made of high-strength alloys or stainless steel. Heavy-duty inserts maintain their sharpness and wear resistance under these high-load conditions, improving productivity while reducing tool wear.

3. Aerospace and Military: Suitable for machining titanium alloys, high-temperature alloys, or stainless steel. Stable machining is achieved while ensuring precision.

Heavy-duty cutting inserts are resistant to chipping and are suitable for intermittent cutting or roughing. Coating technology extends tool life and reduces downtime caused by frequent tool changes. They maintain surface quality even at high depths of cut and feed rates. Contact us today for a quote and information on heavy-duty cutting inserts.