产品中心

PRODUCTS CENTER

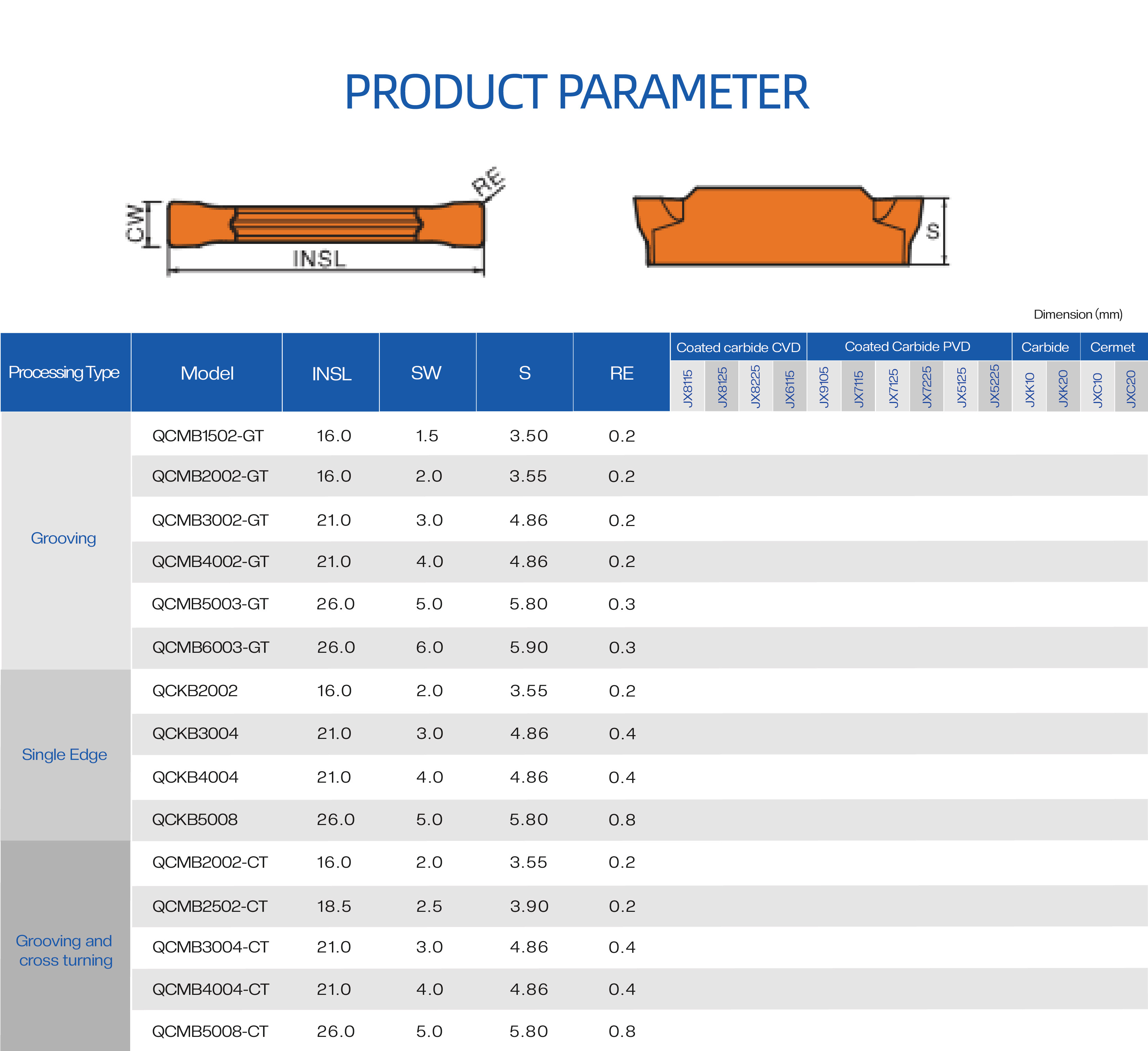

QCKB2002 serie grooving insert universal

Category

Product description

- Product description

- 临床图片

-

- Commodity name: QCKB2002 serie grooving insert universal

CNC grooving inserts work by removing material from the workpiece through a cutting action. The inserts are mounted onto the tool holder of the CNC machine and are rotated at high speeds to create the groove or slot. The cutting process can be performed in different directions, including axial, radial, or tangential, depending on the type of grooving insert used and the design of the workpiece.

High Performance CNC INSERT SERIES

Efficient processing

JX CNC inserts are made of cemented carbide, which have good hardness and wear resistance, and can achieve high-speed and efficient cutting.

Excellent cutting quality

The shape and the cutting edge angle of JX CNC inserts can be adjusted according to the different processing materials, which can achieve high-precision and high-quality processing effects.

Versatility

JX CNC inserts are suitable for a variety of processing processes, such as milling, turning, drilling, etc., which can achieve a variety of different cutting tasks and improve production efficiency.

Environmental friendly

Compared with traditional cutting tools, the replaceability and high efficiency of JX CNC inserts can reduce waste and energy waste, and reduce environmental pollution and production costs.

Keywords:

Keywords:- CNC inserts

- Grooving inserts