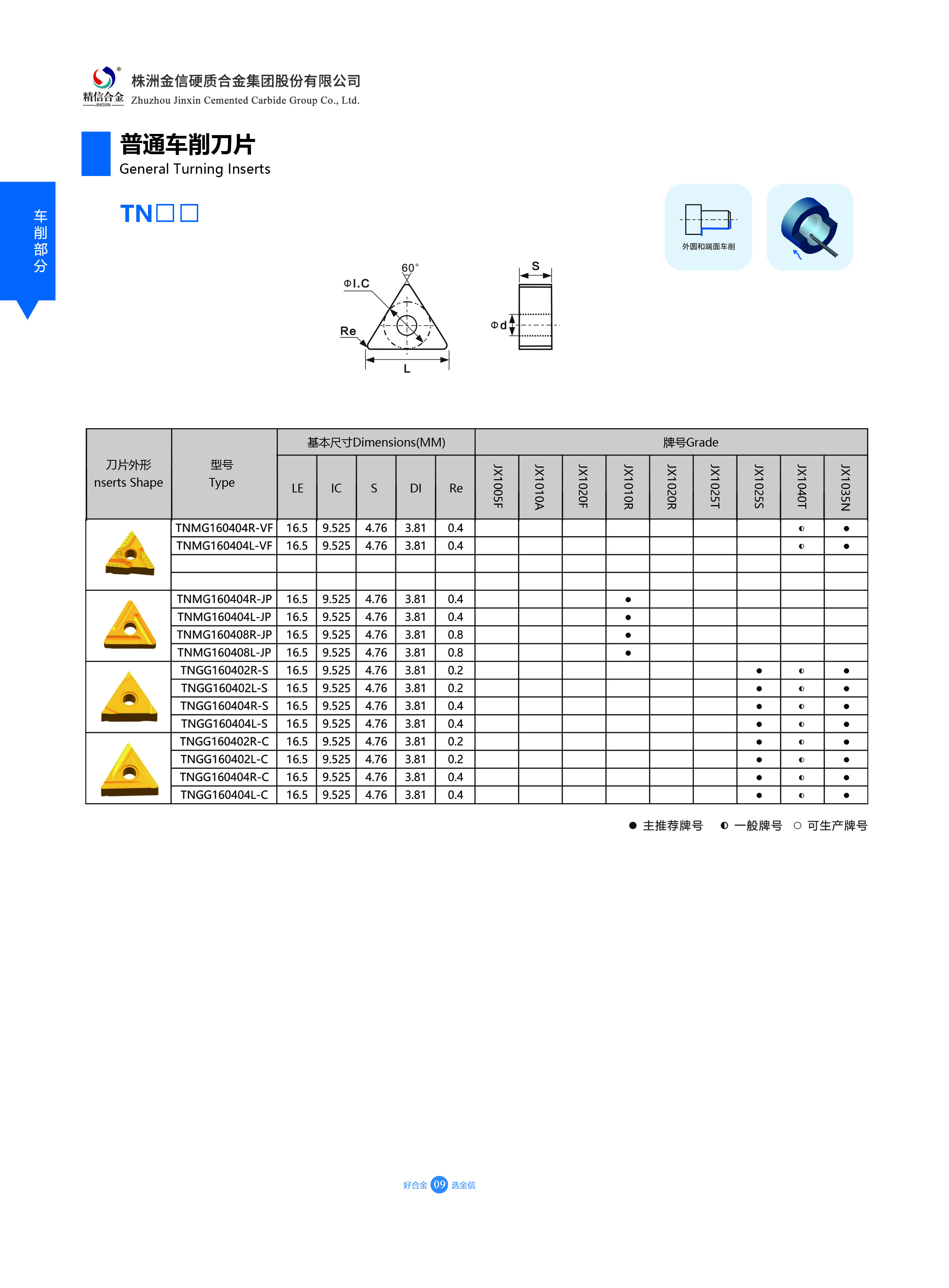

Mechanical Manufacturing

Machining automotive transmission system parts, such as gears, shafts, etc. Turning inserts can be used for roughing and finishing to meet different accuracy requirements.

Aerospace manufacturing, the materials of these parts are usually high temperature alloys, titanium alloys and other difficult-to-machine materials, which require extremely high performance of turning inserts.

Processing of aircraft structural parts, such as fuselage frames, wings, etc.. High-precision turning machining is required to ensure the assembly accuracy and aerodynamic shape of the parts.