产品中心

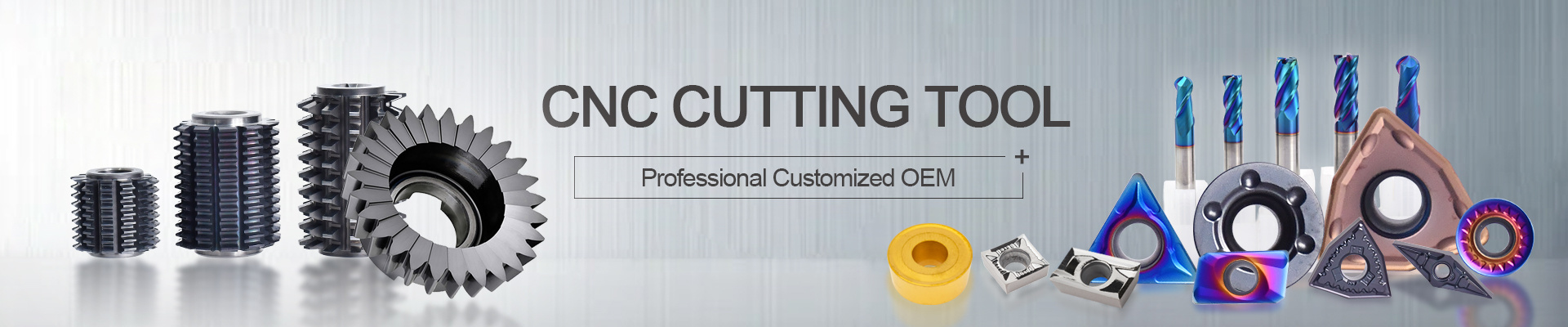

PRODUCTS CENTER

SPMG140512 TG Turning Tool Carbide Insert 6118

Category

Product description

- Product description

- 临床图片

-

- Commodity name: SPMG140512 TG Turning Tool Carbide Insert 6118

We aim to OEM and cutomized order, we have the capacity of new design mold manufacturing for non standard carbide insert, cutting tools production. Please contact and leave your request to us, we will offer the best quotation to you.

Description

- -Turning insert brand: Jinxin

- -Blade back angle: Negative angle Turning insert

- -Processing materials: steel parts, stainless steel, cast iron

- -Processing requirements: rough machining, semi-finishing, finishing

- -Processing method: continuous processing, intermittent processing

- -Blade groove shape: through groove

- -Blade shape: S

Turning inserts are usually made of advanced materials and coating technologies that are able to withstand the high temperatures and pressures generated during high-speed cutting. This allows higher cutting speeds to be used in turning operations, which greatly improves machining efficiency. For example, some high-performance turning inserts can cut steadily at thousands of revolutions per minute, increasing machining speeds by several times compared to conventional tools.

Advantages

Improvement of machining efficiency: specially designed for stainless steel materials, turning inserts for machining stainless steel can achieve higher cutting speed and feed under the premise of guaranteeing the machining quality, thus greatly improving the machining efficiency.

Guaranteed machining quality: good surface finish and dimensional accuracy can be obtained to meet the machining requirements of various high-precision parts.

Reduce cost: by improving the service life and machining efficiency of turning inserts, it can reduce the production cost and improve the economic efficiency of the enterprise.High Performance CNC INSERT SERIES

Efficient processing

JX CNC inserts are made of cemented carbide, which have good hardness and wear resistance, and can achieve high-speed and efficient cutting.

Excellent cutting quality

The shape and the cutting edge angle of JX CNC inserts can be adjusted according to the different processing materials, which can achieve high-precision and high-quality processing effects.

Versatility

JX CNC inserts are suitable for a variety of processing processes, such as milling, turning, drilling, etc., which can achieve a variety of different cutting tasks and improve production efficiency.

Environmental friendly

Compared with traditional cutting tools, the replaceability and high efficiency of JX CNC inserts can reduce waste and energy waste, and reduce environmental pollution and production costs.

Keywords:

Keywords:- cutting Insert

- carbide insert

- OEM Insert

- Turning insert

- SPMG140512 TG