产品中心

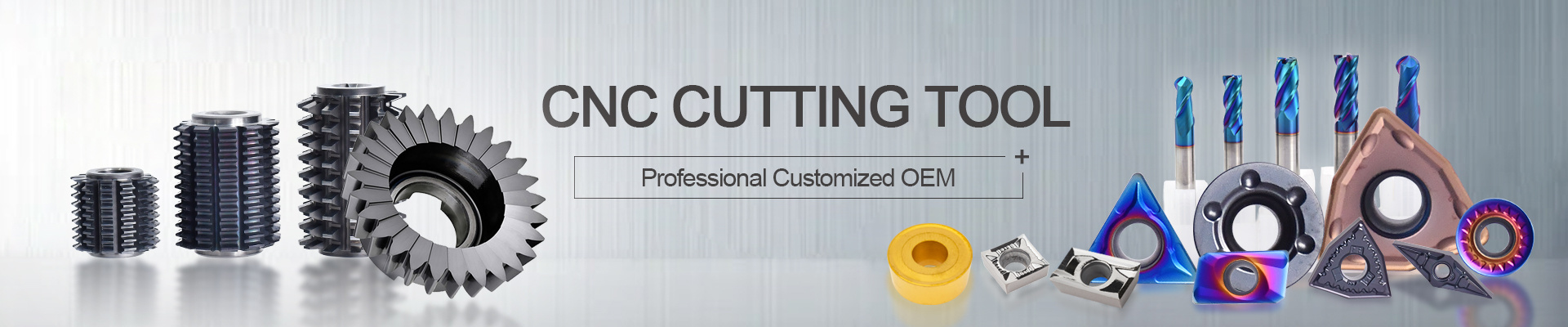

PRODUCTS CENTER

CCGT060202R-U Turning Insert Carbide Inserts 6018

Category

Product description

- Product description

- 临床图片

-

- Commodity name: CCGT060202R-U Turning Insert Carbide Inserts 6018

We aim to OEM and cutomized order, we have the capacity of new design mold manufacturing for non standard carbide insert, cutting tools production. Please contact and leave your request to us, we will offer the best quotation to you.

Description

Finishing turning inserts are usually made of high performance materials such as carbide and ceramic. These materials have high hardness, high wear resistance and good thermal stability, and are able to maintain a sharp cutting edge under high-speed cutting conditions, thus achieving high-precision machining.

- -Insert brand: Jinxin

- -Insert back angle: Negative angle turning insert

- -Processing requirements: rough machining, semi-finishing, finishing

- -Processing method: continuous processing, intermittent processing

- -Blade groove shape: through groove

- -Blade shape: C

- Precision Geometry: The cutting edges of the inserts are carefully designed with specific angles and curvatures to reduce cutting forces, reduce the generation of cutting heat and improve the quality of the machined surface.

- Sharp cutting edges: The cutting edges of the finishing turning inserts are very sharp, enabling tiny depths of cut and feeds to be achieved, resulting in extremely high machining accuracy and surface finish.

- Reliable chipbreaking performance: During the machining process, the inserts can effectively control the shape and length of the chips to avoid the chips from wrapping around the workpiece or tool, ensuring the continuity and stability of the machining.

Efficient processing

JX CNC inserts are made of cemented carbide, which have good hardness and wear resistance, and can achieve high-speed and efficient cutting.

Excellent cutting quality

The shape and the cutting edge angle of JX CNC inserts can be adjusted according to the different processing materials, which can achieve high-precision and high-quality processing effects.

Versatility

JX CNC inserts are suitable for a variety of processing processes, such as milling, turning, drilling, etc., which can achieve a variety of different cutting tasks and improve production efficiency.

Environmental friendly

Compared with traditional cutting tools, the replaceability and high efficiency of JX CNC inserts can reduce waste and energy waste, and reduce environmental pollution and production costs.

Keywords:

Keywords:- turning insert

- carbide insert

- CNC insert

- OEM insert

- china carbide inserts

- Finishing turning inserts

- CCGT060202R-U