产品中心

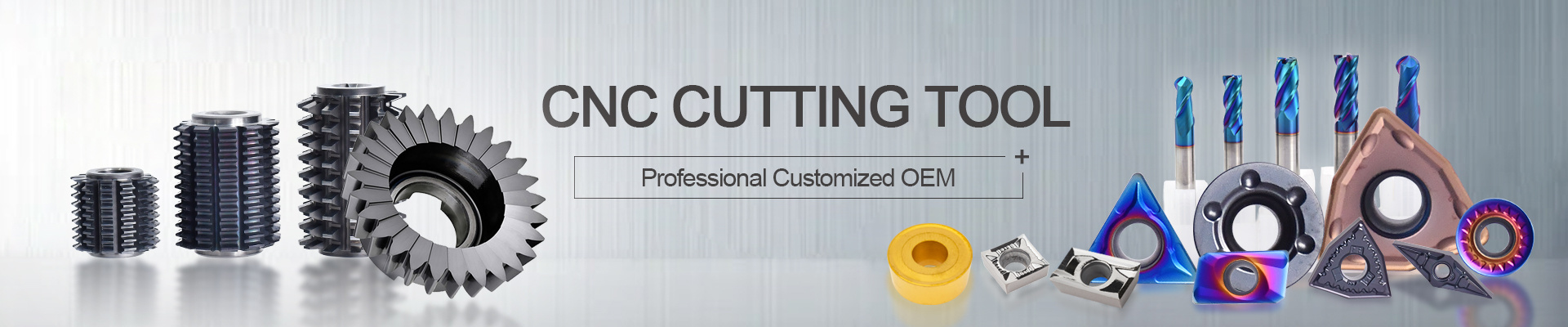

PRODUCTS CENTER

MGNM250-M Cutting Inserts

Category

Product description

- Product description

- 临床图片

-

- Commodity name: MGNM250-M Cutting Inserts

CNC grooving inserts work by removing material from the workpiece through a cutting action. The inserts are mounted onto the tool holder of the CNC machine and are rotated at high speeds to create the groove or slot. The cutting process can be performed in different directions, including axial, radial, or tangential, depending on the type of grooving insert used and the design of the workpiece.

We aim to OEM and cutomized order, we have the capacity of new design mold manufacturing for non standard carbide insert, cutting tools production.

Please contact and leave your request to us, we will offer the best quotation to you.

We are professional tungsten carbide cutting tools manufacturer.Please adjust the parameters according to the material and hardness of workpiece.

We have large quantity standard type tungsten inserts, garantee the faster delivery. 100% brand new and high quality.

Made of high quality materials, durable Product category: CNC blades Processing type: outer circle, inner hole, end face

Thread, groove Coating :CVD PVD ISO

Blade material classification: Steel parts :P05 P25 P40

Stainless steel :M05 M25 M40

Cast iron :K05 K25 K30

Machining accuracy :04 08 12 16 24

Application: Used for cutting steel, cast iron, stainless steel and other parts Material: tungsten carbide

Color: Gold, bronzer, black ,silver

High Performance CNC INSERT SERIES

Efficient processing

JX CNC inserts are made of cemented carbide, which have good hardness and wear resistance, and can achieve high-speed and efficient cutting.

Excellent cutting quality

The shape and the cutting edge angle of JX CNC inserts can be adjusted according to the different processing materials, which can achieve high-precision and high-quality processing effects.

Versatility

JX CNC inserts are suitable for a variety of processing processes, such as milling, turning, drilling, etc., which can achieve a variety of different cutting tasks and improve production efficiency.

Environmental friendly

Compared with traditional cutting tools, the replaceability and high efficiency of JX CNC inserts can reduce waste and energy waste, and reduce environmental pollution and production costs.

Keywords:

Keywords:- cutting Insert

- carbide insert

- OEM Insert

- MGNM250-M