产品中心

PRODUCTS CENTER

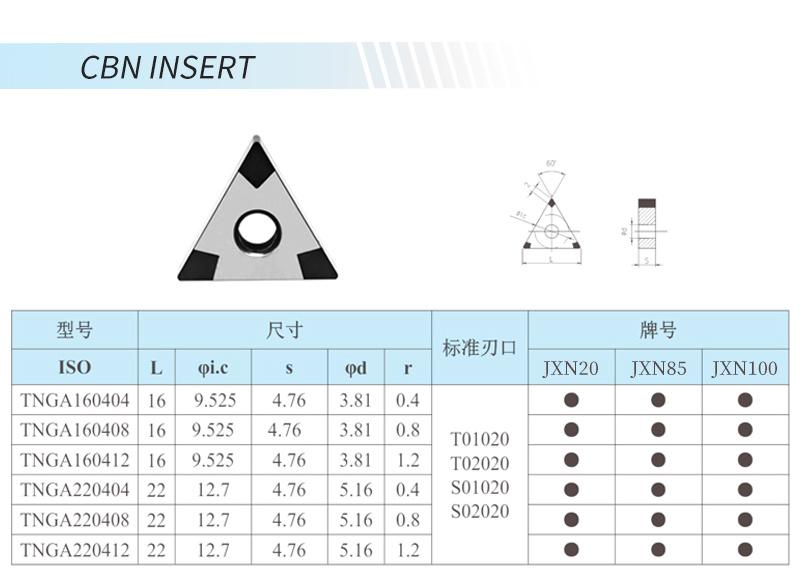

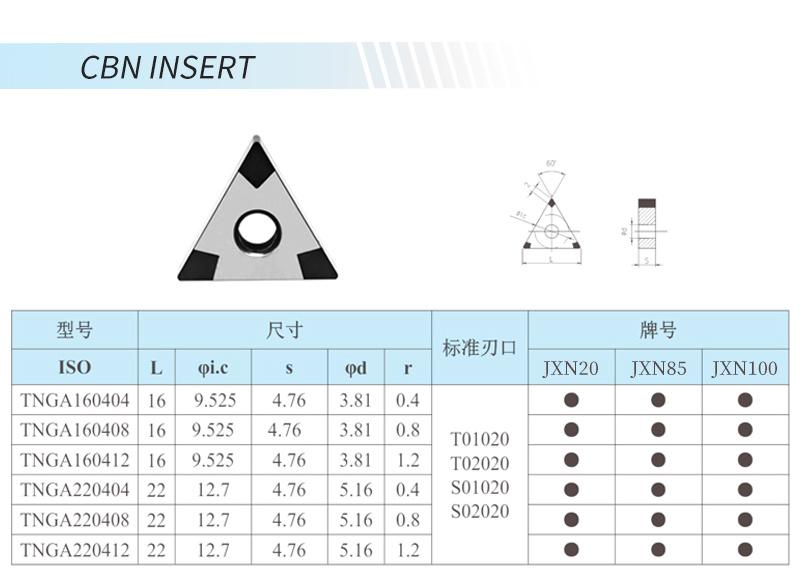

PCBN-TNGA160404-6N CBN PCD Inserts Turning Tool

Category

Product description

- Product description

- 临床图片

-

- Commodity name: PCBN-TNGA160404-6N CBN PCD Inserts Turning Tool

PCBN tool inserts are typically used for finishing operations, where a high-quality surface finish is required. PCD tool inserts are used for a wide range of applications, including turning, milling, and drilling. They are especially useful for machining hard materials like cast iron, high-speed steel, and powder metal alloys. Both CBN and PCD tool inserts offer higher cutting speeds and longer tool life, which can lead to increased productivity and reduced machining costs. They also offer greater wear resistance and improved surface finish.

PCBN and PCD Inserts

PCBN (Polycrystalline Cubic Boron Nitride) inserts are ultra-hard cutting tool materials made by sintering cubic boron nitride (CBN) micropowder under high temperature and pressure. They exhibit exceptional hardness, wear resistance, and thermal stability, making them ideal for machining high-hardness materials.

PCD (Polycrystalline Diamond) inserts are cutting tools made from synthetic diamond particles sintered together under high pressure and temperature. Known for their exceptional hardness, wear resistance, and thermal conductivity, PCD inserts are ideal for machining non-ferrous and non-metallic materials.

Features:

-

High Hardness: Second only to diamond, capable of machining materials with hardness above HRC 65.

-

Excellent Wear Resistance: Long service life reduces tool changes and improves machining efficiency.

-

High Thermal Stability: Maintains superior cutting performance at high temperatures, suitable for high-speed machining.

-

Strong Chemical Inertness: Resistant to reactions with iron-group elements, ideal for machining steel materials.

High Performance CNC INSERT SERIES

Efficient processing

JX CNC inserts are made of cemented carbide, which have good hardness and wear resistance, and can achieve high-speed and efficient cutting.

Excellent cutting quality

The shape and the cutting edge angle of JX CNC inserts can be adjusted according to the different processing materials, which can achieve high-precision and high-quality processing effects.

Versatility

JX CNC inserts are suitable for a variety of processing processes, such as milling, turning, drilling, etc., which can achieve a variety of different cutting tasks and improve production efficiency.

Environmental friendly

Compared with traditional cutting tools, the replaceability and high efficiency of JX CNC inserts can reduce waste and energy waste, and reduce environmental pollution and production costs.

Keywords:

Keywords:- carbide insert

- OEM Insert

- CBN Inserts

- TNGA1604

- pcd insert

- Turning insert