-

-

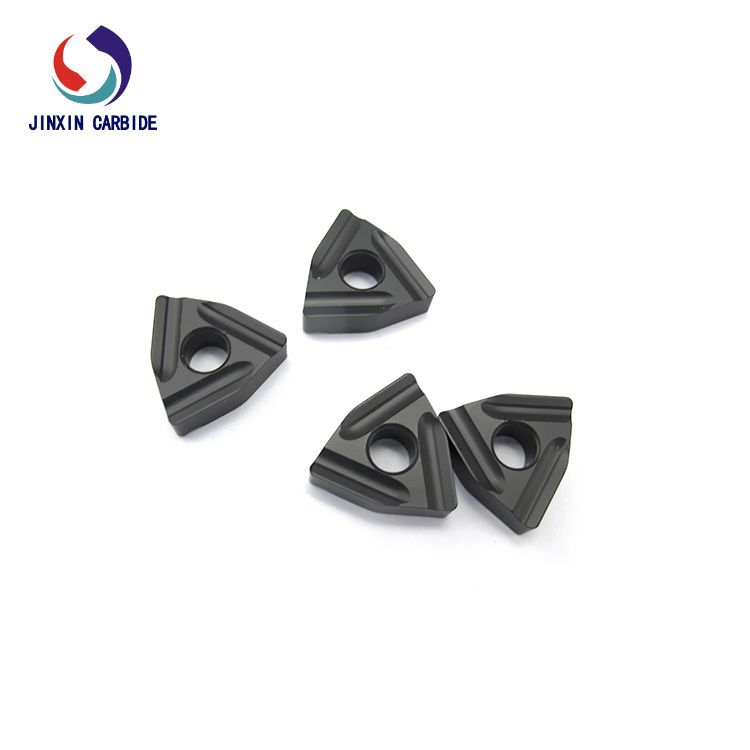

PRODUCTS

-

SERVICE SUPPORT

22

2023

-

09

How to avoid the common problems of turning inserts?

In order to avoid the common problems of turning inserts, we can refer to the following suggestions:

Choose the right insert: choose the right turning insert according to the machining material and workpiece type. Different blades are suitable for different materials and processing requirements.

Proper tool geometry: Use correct tool geometry, such as cutting angle, tool tip radius and cutting depth, to ensure that the cutting process is effective and will not lead to excessive blade wear.

Maintain stable cutting conditions: control cutting speed, feed speed and cutting depth to ensure normal operation range. Excessive cutting speed or feed speed may lead to premature wear of the blade.

Keep the tool cool: use cutting fluid or cooling lubricant to cool the tool and workpiece to reduce friction and prolong the life of the blade.

Check the blade regularly: check the blade regularly for wear or damage. Damaged blades may lead to bad machining results.

Suitable workpiece materials and pretreatment:

Select the appropriate workpiece material and carry out appropriate pretreatment when necessary to reduce the difficulty in the machining process.

Use appropriate machine tools and cutting conditions:

Select suitable machine tools and appropriate cutting conditions to ensure the stability and accuracy of the cutting process.

According to the requirements of specific applications and machines, it may be necessary to formulate detailed technological processes and operating procedures. It is best to follow the manufacturer's recommendations, including usage parameters, blade replacement frequency and maintenance requirements. Zhuzhou Jinxin Group is willing to help you.

Related news