-

-

PRODUCTS

-

SERVICE SUPPORT

06

2024

-

03

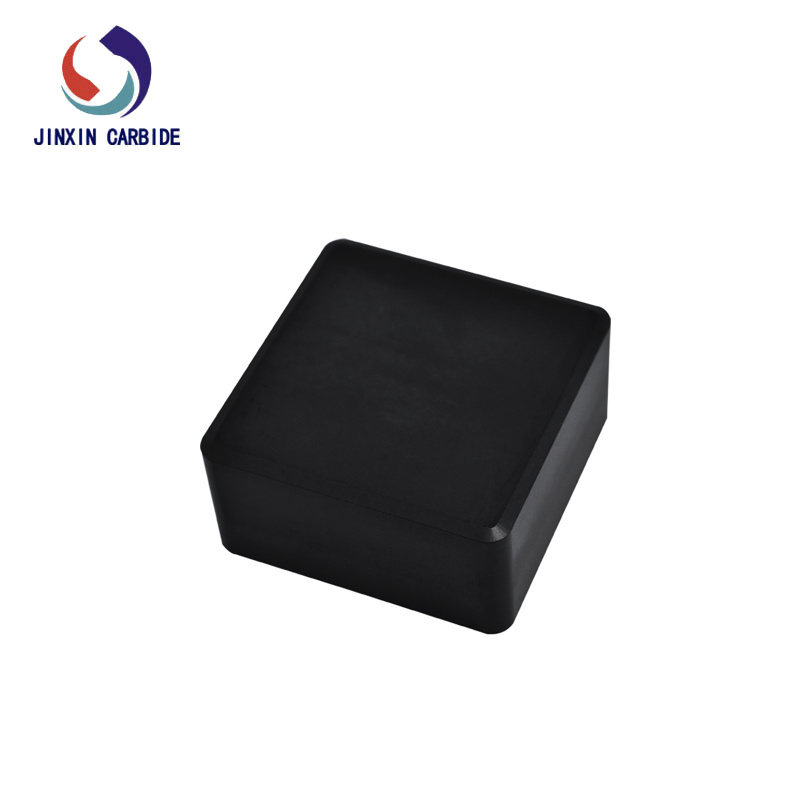

Cubic boron nitride insert

cubic boron nitride insert is synthesized using artificial methods under high temperature and high pressure conditions, combining cubic boron nitride powder with a small amount of binder.

Its hardness ranks second only to diamond and surpasses that of other materials significantly. Therefore, it is collectively referred to as a superhard tool along with diamond tools.

According to the added composition, there are two categories: PCBN directly sintered from CBN single crystal and PCBN sintered body with a certain proportion of binder; According to the manufacturing composite method, there are two categories: the whole PCBN sintered block and the PCBN composite sintered with cemented carbide. The most widely used is PCBN composite sheet with binder. The hardness of PCBN is different according to the proportion of binder added. The more binder content, the lower the hardness and the better the toughness; Different types of binders, the use of PCBN is also different, as shown in Table 1 for common binder PCBN tool and its use.

CBN content (%)- Binder type - Main use

Tipped PCBN tool structure for high-speed finishing, can be used for intermittent processing of hardened steel.

~ 60-TiN- hardened steel

~ 70-TiC- Cast iron

~ 70-Al2O3- cast iron

~ 90-AlN- High strength cast iron

~ 80-Co- heat-resistant alloy steel cast iron

Cubic boron nitride insert is mainly used in gray cast iron, wear-resistant cast iron, a variety of high hardness materials (such as hot and cold tool steel, high-speed steel, bearing steel, powder metallurgy steel, powder smelting metal, martensitic stainless steel, high strength steel, high manganese steel, white cast iron, austenitic iron, etc.) cutting processing.

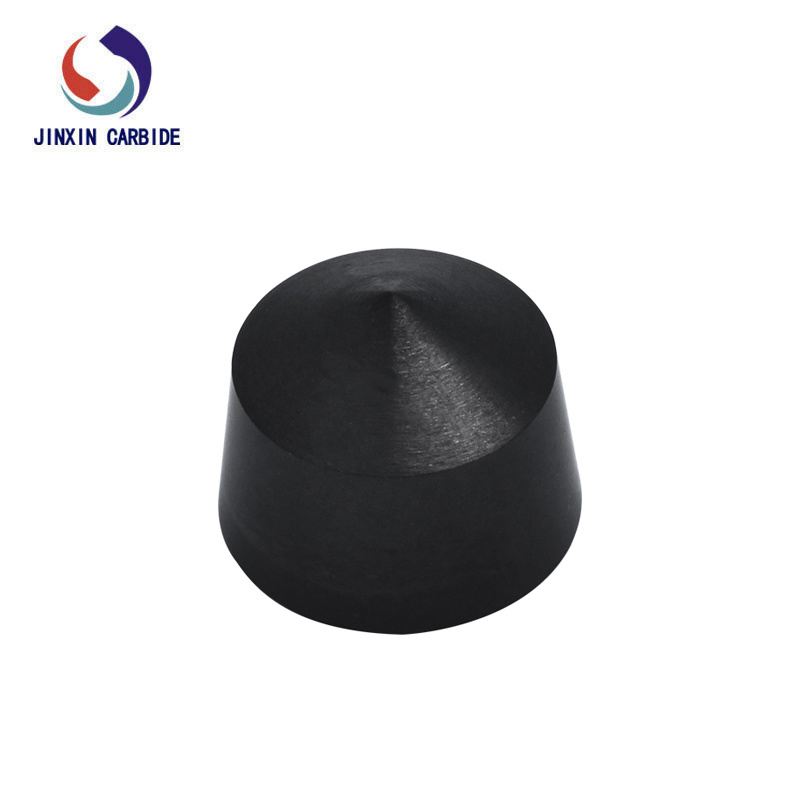

Application characteristics of welding compound cubic boron nitride insert

Welding compound cubic boron nitride tool is mainly used for finishing, due to its poor toughness, impact resistance (more brittle) is insufficient, can not withstand a slightly larger cutting force (related to the tool Angle size), in intermittent processing is easy to break the knife, in use when the depth of the knife (unilateral processing allowance) is best below 0.2mm, the use of high-speed cutting (can not choose low speed), The wear resistance and heat resistance of this material are very good, but the sharpening requirements are high.

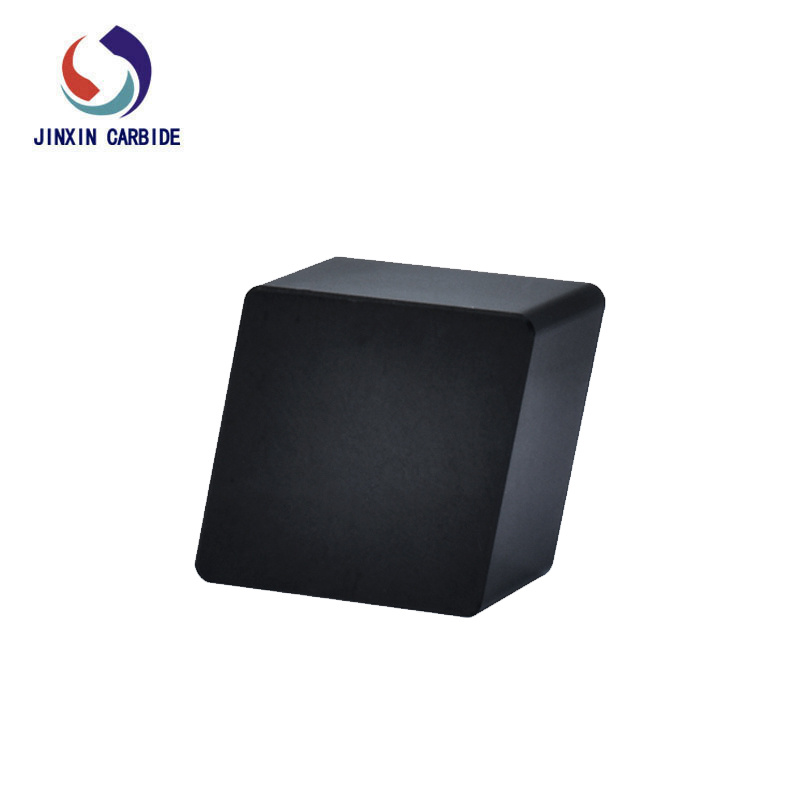

Application characteristics of integral cubic boron nitride insert

Integral cubic boron nitride sheet can be intermittent processing, and encounter sand, white casting does not break the edge, in the actual production application, if the welding compound cubic boron nitride tool break the edge, or need to rough machining, finishing a knife to complete, often use the integral cubic boron nitride (PCBN) insert

Related news