19

2025

-

04

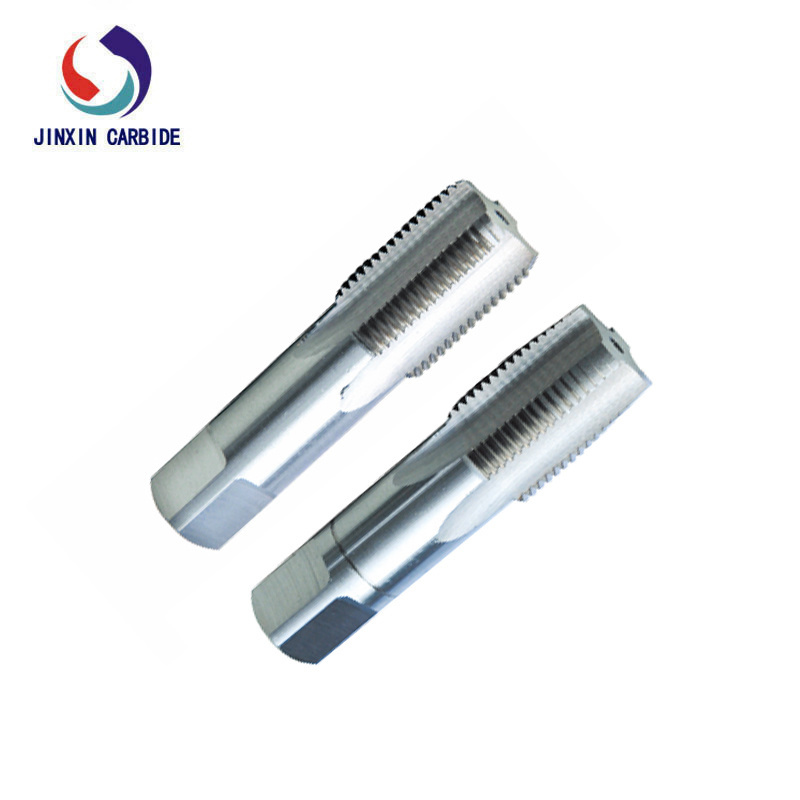

What are carbide taps used for?

Carbide taps are a high hardness, wear-resistant threading tool designed for hard-to-cut materials such as stainless steel and titanium alloys. It has a hardness of HRA 90-94, which is more than 2 times that of high speed steel (HSS). It can work stably in 800-1000°C environment. Common types include straight flute taps, spiral flute taps, extrusion taps, etc., suitable for different materials.

Carbide taps are commonly used in, for example, aircraft engine bolt holes, titanium alloy structural parts threading. Carbide taps can avoid burrs and deformation. Threading of engine block, gearbox housing and other high-strength cast iron/alloy steel parts; tapping of stainless steel housing threaded holes for electric vehicle battery packs; high hardness alloy internal threads for oil drilling equipment, nuclear power valves, tiny threads (e.g., M1.0-M3.0) in metal casings for cell phones/computers, and precision tapping of titanium alloy screw holes for surgical instruments.

When processing stainless steel, the life of Jinxin carbide taps can reach more than 50,000 times, and it can cut materials with hardness HRC 45+ (such as hardened steel and nickel-based alloys). Thread roughness Ra≤0.8μm, reducing the subsequent polishing process, especially suitable for hydraulic sealing threads.

Spiral groove taps can automatically remove chips to avoid cutting blockage, reducing tool change time and scrap rate.

Related news