01

2025

-

08

How to Choose Turning Insert?

The choice of turning inserts primarily depends on the workpiece material, as different materials require varying levels of insert hardness, wear resistance, and heat resistance. For example, carbide inserts are suitable for carbon steel, while PVD-coated inserts—offering enhanced chip resistance—are recommended for stainless steel. When machining aluminum alloys, sharp uncoated carbide or PCD inserts are preferred to minimize built-up edge.

In addition to material compatibility, insert geometry and rake angle design significantly influence performance during both roughing and finishing operations. Common insert shapes—such as diamond, triangle, and round—each offer specific advantages. Selecting the appropriate tool tip shape and rake angle helps achieve optimal cutting results.

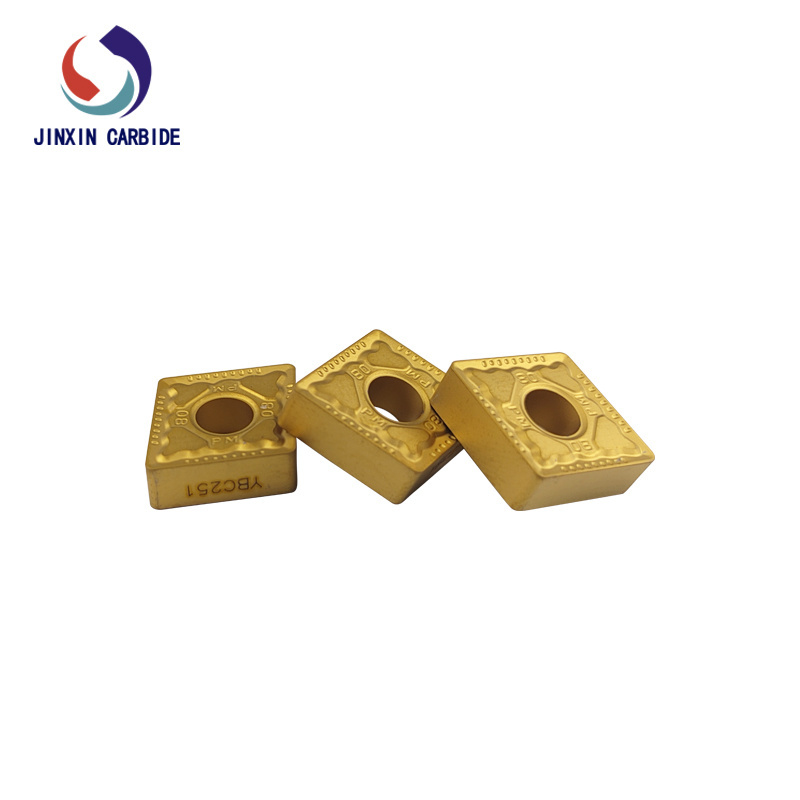

Roughing typically involves removing 3–5 mm of stock, which generates high cutting forces and vibration. Therefore, inserts with a negative rake angle (-5° to -10°) are recommended for greater edge strength. A rake angle between 0° and 5° can guide chips away from the machined surface, helping to avoid scratches. CNMG inserts (80° diamond shape) with a chipbreaker design are recommended for rough turning of forged and cast steel, as they efficiently break continuous chips. An insert thickness of 4.76 mm or greater is recommended to ensure sufficient bending resistance.

For small finishing allowances (0.1–0.5 mm), cutting forces should be minimized to reduce workpiece deformation. Inserts with a positive rake angle (5°–15°) enable smooth cutting, while a rake angle between -5° and 0° improves chip evacuation along the rake face. When machining aluminum alloys, VBMT inserts—with sharp cutting edges and polished rake faces—can achieve a mirror-like surface finish of Ra ≤ 0.8 μm. For stainless steel, inserts with wide chipbreakers are preferred to prevent chip entanglement around the toolholder.

To quickly identify and purchase standard insert models, refer to the ISO numbering system. For example, "CNMG120408-PM" conveys key information such as shape, rake angle, size, and chipbreaker type. Overall, selecting the right high-performance carbide turning insert requires comprehensive consideration of workpiece material, machining conditions, insert geometry, and coating properties. If you have further questions about turning insert selection, please contact us for technical support or custom solutions.

Related news