13

2025

-

06

What is a threading insert?

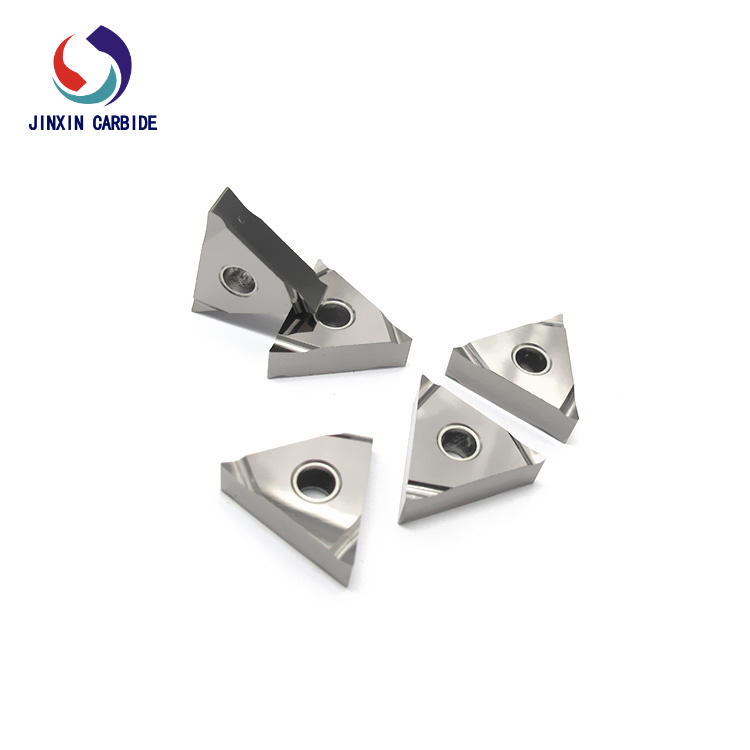

In the field of machining, a threading insert is a type of cutting tool specifically designed for producing threads. Through its specially engineered cutting edges and structural design, it enables the precise formation of standardized thread profiles on a workpiece. These inserts are typically used on CNC lathes or conventional lathes to accurately machine both internal and external threads.

Threading inserts feature specific geometries and cutting edge angles, allowing them to machine various thread standards—such as metric, UN (Unified), British Standard (BSW), and NPT—as well as different thread forms, including triangular, trapezoidal, and round profiles.

Threading inserts are made from a variety of materials, including carbide, ceramic, and high-speed steel (HSS). Carbide inserts are widely used for general metalworking due to their excellent wear resistance and high-temperature tolerance. Ceramic inserts are ideal for high-speed cutting and for machining harder materials. Though HSS inserts are relatively lower in hardness, they offer greater toughness, making them suitable for certain specialized threading applications.

Threading is achieved through a combination of synchronized rotation and axial feed motion. The insert is first precisely mounted on a toolholder and aligned with the center axis of the workpiece. As the workpiece rotates, the insert moves steadily along the axial direction—commonly seen in lathe operations—gradually cutting layers of material to form a complete helical thread groove on the surface.

If you would like recommendations on threading insert brands or guidance on cutting parameters, feel free to contact us!

Related news