24

2025

-

10

what are cermet inserts used for?

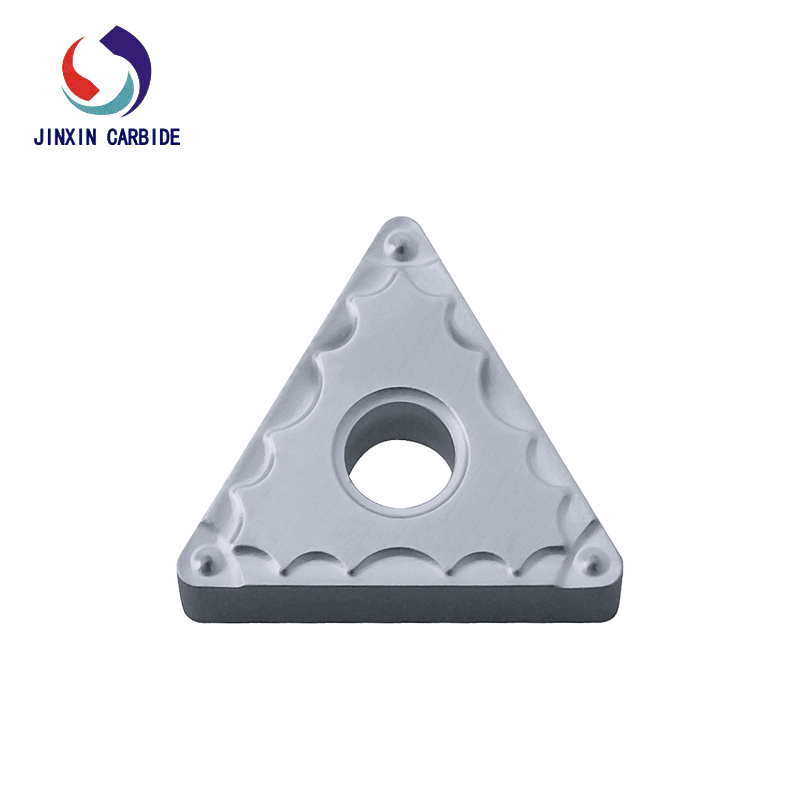

Cermet is a metal–ceramic composite material consisting of hard ceramic particles such as titanium carbide (TiC) and titanium nitride (TiN), bonded together with a metallic binder like nickel or cobalt. This unique combination integrates the superior properties of both materials—offering the high hardness and wear resistance of ceramics along with the toughness and machinability of metals.

Cermet inserts maintain excellent chemical stability even at elevated temperatures and deliver outstanding surface finishes. They are particularly well-suited for continuous, light-load finishing operations where precision and consistency are essential.

Main Applications of Cermet Inserts

1. Finishing and Semi-Finishing of Steel

Cermet inserts excel in the finishing and semi-finishing of low- and medium-alloy steels, carbon steels, and stainless steels. They retain a sharp cutting edge during continuous operations, effectively preventing built-up edge formation. This results in smooth surface finishes, improved dimensional accuracy, and consistent machining performance—making them ideal for stable, high-speed cutting environments.

2. Automotive Parts Manufacturing

In the automotive industry, components such as cylinder liners, piston rings, crankshafts, camshafts, bearing rings, and transmission parts demand exceptional surface precision and dimensional consistency. Thanks to their superior wear resistance and stable cutting performance, cermet inserts help maintain tight tolerances during extended machining cycles while preventing surface scratches, burns, or deformation. This contributes to higher production efficiency and longer tool life.

3. Mold and Precision Component Machining

Mold manufacturing and high-precision mechanical parts processing often involve final finishing of hardened steels and die steels, which require tools with excellent wear resistance and thermal stability. Cermet inserts provide low-friction cutting even at high speeds, effectively dissipating heat and minimizing thermal damage to the workpiece. The result is a near-mirror surface finish with exceptional dimensional control—ideal for fine finishing of mold cavities, precision tooling components, and polishing operations.

Cermet vs. Carbide — Complementary, Not Competing

Cermet inserts are best suited for continuous, high-speed finishing of steel components, whereas carbide inserts perform better under heavy impact loads, interrupted cutting, or cast iron machining. Rather than substitutes, these two materials complement each other in modern machining.

If you're unsure which insert type fits your application best, feel free to contact us for professional recommendations.

Related news